0

WATCHLISTS

You must login before you can use the watchlist functions.

0

BASKET

You must login before you can use the basket functions.

Category

- New in Range

- WS Outdoor 2023

- Pipe systems

- Plumbing installation

- Fixing, insulating, gluing, sealing

- Pipe fittings

- Irrigation, pumps, rainwater utilisation and lifting systems

- Central hoover + laundry chute

- Ball valves

- System separation

- Gas fittings

- Electric hot water tank

- Electronic instantaneous water heater

- GENERAL - replacement parts, installation

Search

Clean separation

System separators ensure clean separation between drinking water systems and downstream devices or pipe installations . They prevent unwanted back pressure, back suction or back flow of contaminated or changed water into the drinking water installation. This effectively prevents clouding of the drinking water quality and even harmful changes to the drinking water.

Effective system separation is therefore required in numerous applications, for example when refilling the heating or when connecting a wide variety of devices to the drinking water network.

Fluid categories

The decisive factor for the selection of a suitable system separator is, among other things, the type of backflowing water against which the drinking water installation needs to be protected. There is a difference between whether the drinking water medium is only clouded in terms of taste by backflowing water, or whether this results in health hazards . For this reason, in order to be able to better classify backflowing liquids and the hazards they pose, they are classified into different categories.

-

Category 1

Liquids in this category include water directly from the drinking water installation that is suitable for human consumption , for example for drinking or cooking. -

Category 2

This category covers water which, although harmless to the human body, may show changes in taste , colour , odour or temperature . -

Category 3

Liquids of this category pose a hazard to humans due to one or more low-toxicity substances , which may be, for example, dishwashing water, cistern water or heating water without additives. -

Category 4

Category 4 includes liquids that pose a significant health hazard to the human body, e.g. due to toxins or radioactive, mutagenic or carcinogenic substances they contain. This may be the case with water containing cleaning agents or heating water with additives. -

Category 5

The highest category includes liquids through which microbial or viral pathogens can be transmitted and which could therefore have a life-threatening effect on the human body.

Effective protection

There are various fittings, equipment and devices available for effective protection of the drinking water system . These include, for example, combined free-flow valve with backflow preventer designed as angle seat valves with an integrated backflow preventer .

|

A combined free-flow valve with backflow preventer is used, for example, at the house connection directly behind the water meter to prevent water flowing back from the domestic system into the public drinking water network. Other controllable backflow preventers also effectively prevent the water from flowing back. They may be used, depending on the version, as type EA e.g. for the protection of non-hazardous liquids up to category 2. |

Complex system separators for the protection of hazardous liquids are designed with three internal chambers and several valves. These include system separator BA and system separator CA . Each of the integrated pressure zones has a lower pressure than the chamber connected upstream in the flow direction. If there is a pressure drop on the inlet side or an excessive pressure rise in the centre chamber, the relief valve of the backflow preventer opens and discharges the water.

- CA system separators can be used to protect liquids up to category 3.

- BA system separators also have control options for the upstream, intermediate and downstream pressure zones. Type BA is suitable for protecting the drinking water system against liquids including category 4.

Other protection options

On the other hand, separating stations are mainly used when the drinking water installation needs to be protected against category 5 liquids. This may be water contaminated with microbial or viral pathogens. This applies, for example, to applications in doctors' surgeries, laboratories or dental practices that want to feed non-potable water applications from the drinking water network.

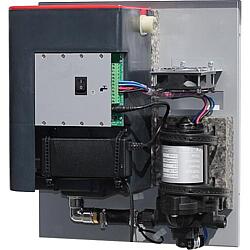

The devices have an integrated pump and a tank completely separated from the drinking water system , from which the subsequent installation is fed, in order to ensure absolutely safe separation of the systems. Being compact separating stations, the units require very little installation space.

The devices have an integrated pump and a tank completely separated from the drinking water system , from which the subsequent installation is fed, in order to ensure absolutely safe separation of the systems. Being compact separating stations, the units require very little installation space.

|

Filling fittings and refilling combinations for heating also generally meet the requirements for protecting liquids of category 3 or category 4. For this purpose, a CA or BA type separator is already integrated into the fitting, as is a pressure reducer , shut-off valves and a pressure gauge .

The system separators must be checked at regular intervals to ensure that they function reliably at all times. The testing of the system separator is ideally done with an appropriate test set . This type of set contains all the tools required for the functional testing of system separators, clearly arranged in a test case . This makes it quick and easy to carry out an annual inspection of the pipe separator. |

Products |